millbrilesabre

Member

- Joined

- Jul 11, 2020

- Messages

- 70

- Reaction score

- 20

- Points

- 8

- Buick Ownership

- 2002 lesabre

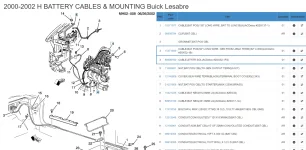

My 02 LeSabre is having alternator problems. I haven't done much testing other than seeing that I'm getting <12v while the car is running, but its the original part with 219k miles on it and I already have a used alternator that I pulled from a junk yard so I was planning to just install that. I think it came from a newer LeSabre but I cant remember for sure now. I grabbed it because the yard was having a 50% off sale and it looked brand new. It is identical to the current alternator in every way except that the stud that the positive wire mounts to is a little bit larger. And I've lost the spacer/sleeve that's supposed to go around that stud between the positive wire terminal and the body of the alternator. The one for my existing alternator doesn't fit.

Just wondering what the best solution would be here? Should I crimp on a larger ring terminal for the positive wire so that it will fit over the larger stud, and then maybe just sandwich it between 2 nuts that fit on that stud?

I could also drill out the existing pieces because they only need to open up a little, but idk if that would reduce their current capacity too much.

Edit - oh and if anyone has any info on when/if the change was made to this version of alternator, please chime in. Maybe it was a certain year or maybe the difference is that this came from a limited and I have a custom? Or maybe I pulled it from a different gm car thinking it would be the same, I don't think I would've done that but cant say for sure now

Just wondering what the best solution would be here? Should I crimp on a larger ring terminal for the positive wire so that it will fit over the larger stud, and then maybe just sandwich it between 2 nuts that fit on that stud?

I could also drill out the existing pieces because they only need to open up a little, but idk if that would reduce their current capacity too much.

Edit - oh and if anyone has any info on when/if the change was made to this version of alternator, please chime in. Maybe it was a certain year or maybe the difference is that this came from a limited and I have a custom? Or maybe I pulled it from a different gm car thinking it would be the same, I don't think I would've done that but cant say for sure now

Last edited: