It is wired in and working, but not gracefully.

Oh damn... this is nice. Much respect for the fabwork involved here.

Best part is showing this kind of thing to my old man who works at the Milford Proving Grounds. He'll say it couldn't be done. It simply doesn't bolt up.

Not at all. I have it stripped down to the bare LCD and even that was too big. I had to hack up my dash...quite a lot. Nothing that some fiberglass, black vinyl die, and a trip to the craft store cant mend but I had to cut so much out it that I was honestly thinking of scrapping the project and buying a new dash. But at the last second! When I thought all hope was lost...I finally was able to consistently get the display in/out and seating pretty nicely.

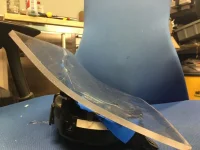

Materials you will need: files, hack saw blades, very sharp blades for your box cutter, a very very very steady hand, heat gun, hot glue gun, and various other grabbing, cutting, and plastic prototyping tools...[would not recommend cyanoacrylate...it bonds very well to the Acrylonitrile Butadiene Styrene that makes up the housing and skeleton of the cluster, but the fumes from the CA will destroy the vinyl dash and the LCD itself...not worth it in my opinion]...Behind the vinyl is a polyPropylene shell that gives it support, this is where you will need the heat gun, stead hand, and sharp knife to cut a smooth consistent edge...sawing will destroy your edge and leave you with a very unsightly final product as will heating too much with the heatgun...so keep it moving. Hot glue is your best friend with an interior. It is strong enough for mile loads, bonds to almost anything, and if you have adjustable heat on your glue gun you wont ever damage the plastic while being able to very very accurately control viscosity to get the perfect seam every time. Totally under rated. I use it for everything from potting electrical connections, casting molds, to tacking things like that screen in place while I glass around it to make a smooth molded surround (make it look like an actual cluster again lol).

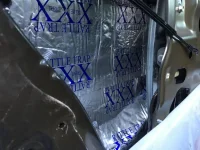

This was months ago though. I have been concentrating on other parts of the car for the most part. Pulled the interior for sound deadening and running of the harness for the IO6 swap. Along with tearing all the doors apart, building speaker baffles, fully deadening the doors, installing speakers+tweeters, making mounting brackets for control modules, taking hole saws to my rear door panels (for the tweeters), while front doors casting the tweeter into the factory enclosure with hot glue for a completely stealth install ...and all other kinds of fun shit.

Sprayed the headliner with liquid deadener, this added a decent amount of heft to the liner and I had to reenforce the velcro mounts with additional high strength velcro. To help road noise in addition to matting both the roof and floors. The entire trunk was done as well. All with 80mil RattleTrap cut to fit, heated to melting point with a heat gun, then rolled on to ensure it will never let go and rattle/collapse the interior carpets.

I finally fixed my driver seat heater after months of putting it off (it actually isnt that bad) for those whos seat heaters crap out on them, 80 bucks for both elements and 2-3 hours of your time.

And finally, since the GS doesnt come with a spare, I Built in some ID8s into a custom fiberglass/High Density Polyethylene sealed enclosure. The ID8s are recessed so the factory trunk floor mat will lay right down on top with some velcro to make sure it is held in place to prevent rattling. The AMPs (two Arc XDi1100.5 and PS8 DSP) are mounted upside down on the rear deck, when complete the wiring is completely tied, tucked, hidden by factory carpet with minimal impact on cargo space/usability. One final mod was the addition of 4 Cree XHP70 LEDs to illuminate the trunk. WOW. Best modification EVER! SO much more usable!

Here are some pics for fun.

holy shit that's a lot of projects going at one time!! Great job and initiative to go places with the car many would be afraid to start. You did to your interior the equivalent of what Kranz did to the motor. Unbelievable things. What do you do for a living because you're really good with electronics and wiring?

holy shit that's a lot of projects going at one time!! Great job and initiative to go places with the car many would be afraid to start. You did to your interior the equivalent of what Kranz did to the motor. Unbelievable things. What do you do for a living because you're really good with electronics and wiring?